Bearings Buying Guide

Are you unsure which bearings you should get? In this guide, we'll explain the most important terms and facts about bearings. We'll also explain which bearings are best for exactly your way of riding or skating.

1. Bearings in general

A wheel needs 2 bearings to rotate on the axle. A bearing can have a big influence on the speed and feel of your riding/skating.

Regardless of the type of bearing you have, you should avoid sand, water and humid conditions at any time, as this will shorten the lifespan of your bearings considerably. Regular cleaning and lubrication of bearings can help to increase their durability and speed. See how to clean your bearings here.

Also, a spacer to fill out the space between the bearings is required, as to avoid destroying the bearings and to create clean rotation when the axles are tightened. The size of the spacer depends on the size of the axle used.

8 mm spacer

6 mm spacer

The quality of bearings depends on a range of factors, such as:

- Material

- Precision (ABEC)

- Lubrication

- Sealed or open (Removable Shield)

Which type of bearing is best for you:

- Are you mainly riding/skating outside, we recommend sealed bearings lubricated with grease,

as these are most resistant to dirt & dust and require low or no maintenance. - Are you mainly riding/skating inside, you can use open bearings that spin fast and are easy to clean.

- Are you interested in speed and long distance runs, you can use high precision bearings lubricated with oil. They spin extremely fast and are easy to clean, but dirt can damage them quickly.

2. Mounting

A bearing can usually be pressed in with your thumbs. When the bearing is mounted correctly, it is in line with the wheel core/hub. If it points out in one corner, it's not mounted correctly and will be destroyed upon skating it. If you have a metal core wheel it can be hard to mount the bearing, in this case, use a rubber hammer or a square piece of wood to knock it in.

Never use a metal hammer as it will destroy the bearing and your warranty.

Alternatively, you can use some lubrication to get a bearing in place, if you do then remember all excess lubrication has to be removed afterwards.

3. Bearings in detail

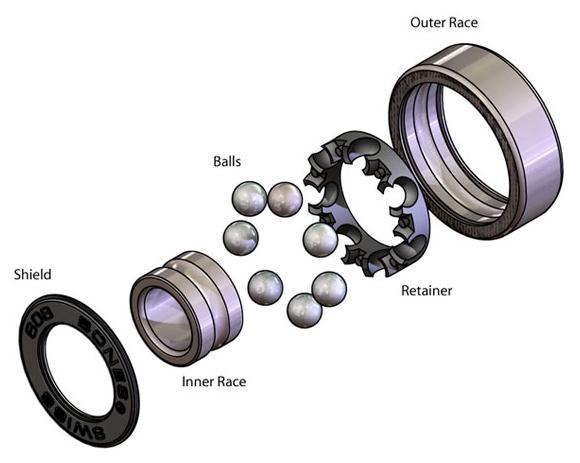

Material

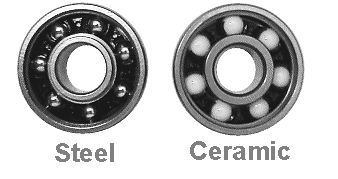

The material of bearings is one of the most important factors for their quality and durability. Most bearings are made of steel. Cheap bearings are usually made of pressed sheet metal or hardened carbon steel, both types are not recommendable for a long lifespan.

Better bearings are made of real bearing-steel, such as chrome, titanium or Swiss steel.

In ceramic bearings (usually used for speed skating) the balls are made of industrial ceramic (Silicon Nitride). Ceramic balls seldom rust and are more durable than steel.

Price and quality are very closely related when it comes to bearings, and you can usually trust the known brands to produce good and durable bearings.

Precision/ABEC

Bearings are categorized according to the industry accepted ABEC-specification. ABEC describes how good bearings are at translating the force applied on them. The higher ABEC classes provide better precision, efficiency, and greater speed capabilities, but do NOT necessarily make the components spin faster. The ABEC rating does not relate to other critical factors, such as the precision of spacers and wheels or the material. All bearings do lose their precision level after some wear.

Please note, that not all brands make use of the ABEC scale (e.g. Bones) and that other scales for bearings exist.

ABEC stands for Annular Bearing Engineering Committee.

Lubrication

Bearings can either use oil or grease as lubrication. A bearing must never run "out" of lubrication, if it does it will melt and lose speed or block completely.

- Oil: Results in high speed because of less resistance in the lubrication material. A thin oil gives higher speed, but also requires more frequent maintenance.

- Grease: It resists water and dirt more than regular oil. Requires almost no maintenance, but creates higher resistance, also means less speed.

Notice: Water can remove all lubrication! If this happens and the water dries, your bearings will get very hot and possibly melt and make sounds, the next time you use them. This means you need to replace the bearings. In some cases, if you have not rolled on them in between, it can be saved if cleaned and oiled properly before the next use.

Shields/Seal

In order to prevent dirt, sand and water to enter the bearings, a shield or seal is often placed on each or one side of the bearing.

- A Shield is usually a metal shield mounted to the outer ring and has a little space to the inner ring (also called a dustproof bearing). Bearings with shields have little friction and therefore rotate more easily, giving you more speed. On the other side is the bearing not perfectly protected against water and dirt.

- A Seal (pictured below) is made of steel-enforced rubber, which is mounted to the outer ring, and slightly touches the inner ring. It gives better protection and almost no maintenance, but also higher friction and slightly lower speed.

4. The standards and bearing precision explained

There are a number of factors covered by the ABEC grades. One is the eccentricity (roundness) of the track in the inner ring. The table below is the maximum eccentricity allowed.

| Type | mm | Inches |

| ABEC 1 | 0.0075 mm | (0.000295") |

| ABEC 3 | 0.0050 mm | (0.000197") |

| ABEC 5 | 0.0035 mm | (0.000138") |

| ABEC 7 | 0.0025 mm | (0.000098") |

| ABEC 9 | 0.0012 mm | (0.000047") |

This means, that the higher the ABEC classification, the smaller the deviation in the parts of the bearing = more power is transferred to the wheel.

ABEC and ILQ cannot be directly compared since ILQ is a brand name and ABEC is a standard.

ABEC bearings are measured on the accuracy in production and not the durability or function under a load. Twincam, the manufacturer of ILQ rates the quality of their bearings on a scale similar to the ABEC scale. But despite that, ILQ bearings has 6 balls, where ABEC bearings have 7.

To clarify the difference, ILQ is not a standard, such as ABEC bearings. ILQ should, therefore, be seen as an unrated bearing from a professional inline bearing manufacturer and is not optimal for industrial machinery.

Bones bearings are made purely for skating - and cannot be compared with ABEC specifications.

The vocabulary for bearings and their shields is listed below (the type of the bearing is usually printed on the bearing together with the size, e.g.: 608ZZ).

608

- Standard bearing

- 22 mm outer diameter

- 7 mm width

- 8 mm inside diameter

688

- Mini/Micro bearing

- 16 mm outer diameter

- 5 mm width

- 8 mm inside diameter

Z

- Shield, 1 metal shield

- Open in the other end for easy maintenance (always turn the open side to the inside of the wheel when mounting)

ZZ

- Shield, 2 metal shields

- The shields are mounted with a small C-ring, which must be removed in order to remove the shield for maintenance.

2RS/RS/RZ

- Seal, 2 steel armed rubber seals

- Seals mounted without C-rings. It is possible to remove the seals carefully with a needle for maintenance.

BRS

- Seal, 2 steel armed rubber seals (contact free)

- Seals mounted without C-rings. With extra good protection against water entering the bearing.