How to Clean and Lubricate Bearings

To ensure optimal performance for your bearings, it's a very good idea to clean and lubricate the bearings on a regular basis. This will preserve the durability and lifetime of your bearings and provide you with optimal speed from your bearings.

Notice: Always avoid water & sand

A bearing's lifespan will be shortened drastically when used/stored in a moist and dirty environment.

How to clean and lubricate bearings on your skates, skateboard and scooter

Step 1

Required tools: Cleansing agent like a grease dissolving fluid, like Fluid wash, a waterproof container, a drawing pin or box cutter, a little brush and new oil/grease.

Remove the bearings from the wheel. Watch the YouTube video at the top on how to remove the bearings from a wheel. The demo is performed on a skate, but the process is the same for skateboards and scooters.

Get the wheels off and dismount the bearings.

Step 2

Use the brush to clean all outside areas of the bearings, so the bearings are completely free of dirt.

There are two kinds of bearings that can be maintained; open and closed. Open bearings are easy to maintain, whereas closed bearings can be maintained by carefully removing the shield.

Clean the outside areas of the bearings.

Step 3

If your bearings are sealed, you can remove the seal with a drawing pin.

On some closed bearings that have metal shields, there is a small C-clip holding them in place. This C-clip must be removed with the drawing pin before the shield can be removed.

Remember to also clean the seals and C-clips if supplied.

Seals (without C-clip) is removed from the bearing with a drawing pin or box cutter.

Step 4

Place the bearings in a closed container that holds the cleaning agent, and then shake the container for a few minutes. This will dissolve any dirt that might have been building up.

First, clean the bearings with a small brush and then use cleansing agent afterward.

Step 5

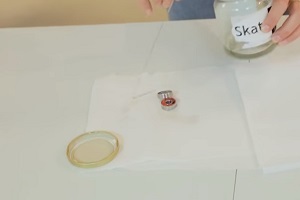

Remove the bearings from the container and remove the rest of the cleansing agent by spinning the bearings. Another good way to do this is by using an air compressor to blow out the fluid. Place the cleaned bearings on a piece of clean cloth or kitchen roll.

The bearings have just been removed from the container holding a cleaning agent.

Step 6

Test if the cleaning process was successful. Hold the bearing on the inner ring and give the bearing a light spin. If the bearing does not rotate freely and/or you hear a crunchy sound, it is because the bearing is not cleaned thoroughly enough. If this is the case, you should repeat the cleaning process with a portion of fresh cleaning agent. For very dirty bearings, it can be necessary to repeat this process 2-3 times.

Test if the bearing is cleaned thoroughly, by spinning it as shown.

Step 7

Place the bearings back on the clean cloth or kitchen tissue. The bearings are now ready for oil or grease. Use 1-2 drops of oil (not more, as it will attract dirt) or 3 mm grease evenly distributed around in the bearing.

Make sure that the oil/grease is distributed well by spinning the bearings (can be done very effectively by mounting the bearing on a drilling machine).

1-2 drops of oil are carefully dripped into the bearing.

Step 8

Finally, place the shields back on the bearings and put the bearings back in the wheels of the skate, skateboard or stunt scooter.

Seals are mounted on the cleaned and lubricated bearings, and the bearings are mounted back on the wheels.

After cleaning and lubrication

After cleaning and lubrication of the bearings, you might need to run a few miles before the oil/grease is perfectly distributed in the bearings, and therefore before the bearings perform optimally.